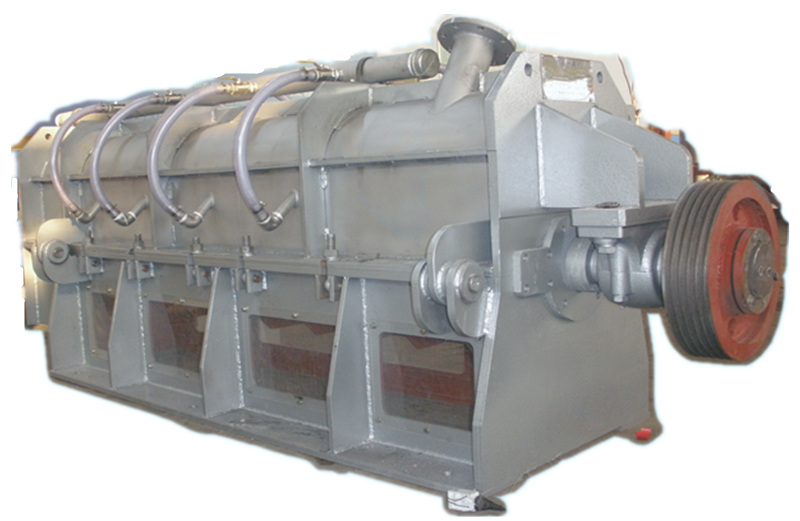

Impurity separating machine is composed of steel cylinder tank, horizontal vane separator, drive motor and inlet pipe, etc.

Owing to action of inner weir plate, heavy impurities are at the bottom, pulp and light impurities will be further deslagged when they enter into cylinder screen through circulation area.

When vane rotates back, pulp flow will be absorbed along center axis, and shot out rapidly from circumference of vane to form fierce turbulence cycle.

Design adjustment check ring to adjust gap between vane and screen board to control quality and quantity of outgoing pulp.

Match with pulper to operate will separate and clear light and heavy impurities from waste paper pulp, so as to improve production capacity of pulp machine.

Carry out effectively coarse slag screen from waste paper pulp to simplify process operation as well as save electricity and reduce energy consumption.

Specification:1.2 m³~5.0 m³